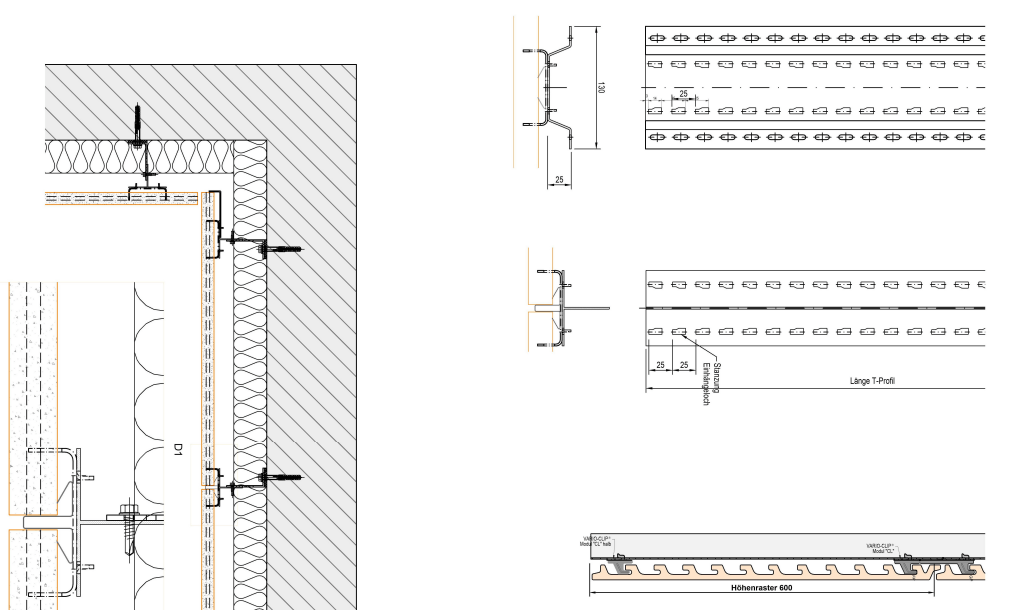

Tonality has now developed a new substructure for fixing its high-quality facade ceramics: the Vario-Clip system. It consists of a support profile with pre-punched suspension points spaced at least 25 millimetres apart. A matching fixing bracket is simply clipped into this grid of holes at any distance – without screws or rivets. The result is a variable standard substructure that flexibly adapts to ceramic elements of any module height. The Vario-Clip system is available from stock and offers a high degree of planning and system security, as well as enabling a significant reduction in material and simplifying installation.

Flexibility in terms of time and planning as well as safety and sustainability aspects are among the main factors that led to the new development of the Vario-Clip system by Tonality (Leipfinger-Bader group of companies). The substructure for fixing ceramic elements for façade design differs fundamentally in its systematics from conventional substructures. Whereas previously individually calculated system rails were screwed and riveted to the support profile, Vario-Clip works according to the plug-and-ready principle. First, a support or cap profile with a special hole pattern is fixed vertically to the façade. The special feature: The factory-prepared suspension points of the hole grid are only 25 millimetres apart. The new Vario-Clip mounting system can be snapped into these points in a few simple steps. The exact positioning can be flexibly selected and adjusted according to the respective grid height of the ceramic elements. Ceramic tiles of different sizes are then clipped in horizontally. A matching joint profile completes the Vario-Clip system.

Less is more

The advantages of the new system are obvious. There are no screws, rivets or drilling required. There are no fasteners between the support profile and the system fixing bracket, which greatly simplifies and speeds up installation. Figures from the field prove the enormous savings potential: around 3,300 ceramic elements with a module height of 300 x 1,000 millimetres fit on a façade area of around 1,000 square metres. With this surface area, up to 13,000 fasteners can be saved. “There is currently no other fastening system for façade elements on the market that works without rivets or screws. We are pioneers in this field, and this is yet another convincing argument for our ceramic façades, which are unique in every respect,” says Michael Klein, Key Account Manager at Tonality. Further material savings are achieved by the fact that the aluminium mounting bracket consists of short pieces rather than continuous rails. This simplifies both transport and shipping.

Sustainable quality

The Vario-Clip system is also impressive in terms of safety. The prefabricated support components offer a high level of project quality and minimise potential sources of error during planning, procurement and installation. For example, centric load transfer into the support profile is generally ensured, as the pre-punched suspension points precisely define the fixing.

With the new Vario-Clip system, Tonality now offers, in addition to the existing substructures, a standardised variant that is quickly available from stock and can be used universally, regardless of the project. This eliminates lead times for project-specific production. In addition, repeat orders are simplified and surplus quantities can be used flexibly for other projects. In addition to significant material savings, this is another aspect of sustainability in terms of resource-saving construction.

Planning documents for the Vario-Clip can be downloaded directly from the download area.